Advanced. Integrated. Undisputed.

International® S13 Integrated Power Train

A clean sheet of paper and decades of experience. That’s what the engineering team started with when they began work on the International S13 Integrated Powertrain. And this wasn’t any team. This was a dream team of engineers located literally all over the world. It was thanks to this spirit of partnership, this deep collaboration between companies, that we were able to shift what’s possible and rethink, redesign and reinvent what an integrated powertrain can be.

UP TO A 15% BOOST IN EFFICIENCY*

DELIVERING SUPERIOR OPERATIONG ECONOMY

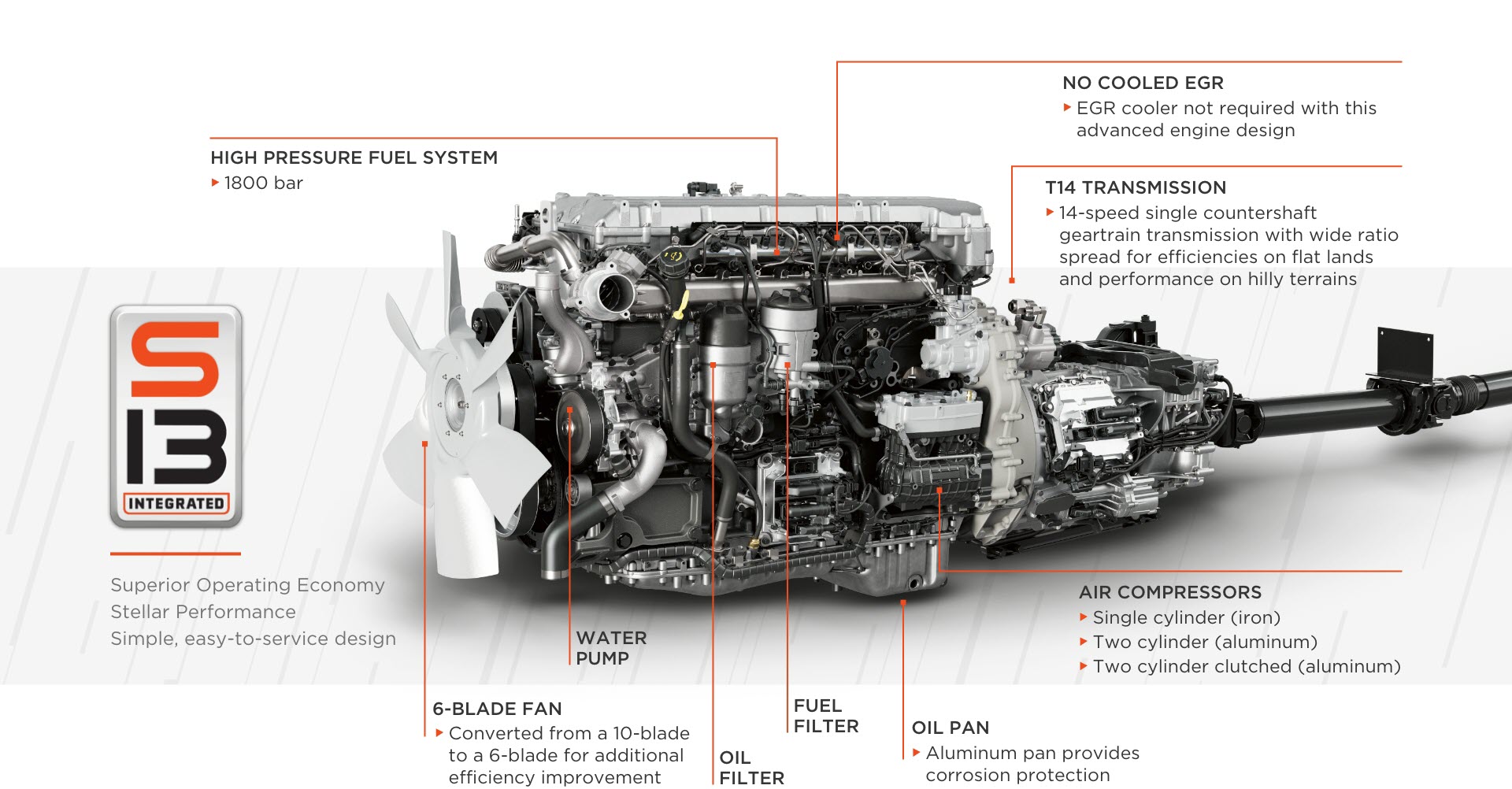

Through exhaustive simulation work, a new cylinder and piston head design with maximum cooling properties was created. This new double overhead cam design directly equates to less fuel being consumed. But that’s not all. Thanks to the new Dual Stage Aftertreatment system, the heavy (40-50 lbs), expensive ($2,500 approx.) and finicky EGR cooler is no longer needed to reduce emissions. Its absence not only contributes to the S13 being the lightest 13-liter diesel engine available in North America, but it also means 100% of the exhaust flow goes through the new simple, more reliable fixed-vane turbo charger for maximum performance and efficiency.

DELIVERING THE GOODS

The S13 Engine can operate at low RPMs with high torque which equates to less fuel consumed while still delivering up to 515 horsepower and 1,850 lb-ft of torque. This incredible engine brings undisputed economy through combustion efficiency, the reduction of friction and pumping losses, and through use of new integrated software and controls.

*Comparing the fuel economy of the 2017 GHG International® A26 engine in a 2017 International® LT® Series truck with aero package to the fuel economy of the new International® S13 Integrated Powertrain in a 2024 International® LT® Series truck with the LT aero package and chassis enablers. Actual customer results may vary due to various factors, including but not limited to, truck specifications, weight of the vehicle, predictive features, environmental conditions, etc.

a DRIVER'S ENGINE

PROVIDING STELLAR PERFORMANCE FOR THOSE BEHND THE WHEEL

A clean sheet of paper and decades of experience. That’s what the engineering team started with when they began work on the International S13 Integrated Powertrain. And this wasn’t any team. This was a dream team of engineers located literally all over the world. It was thanks to this spirit of partnership, this deep collaboration between companies, that we were able to shift what’s possible and rethink, redesign and reinvent what an integrated powertrain can be.

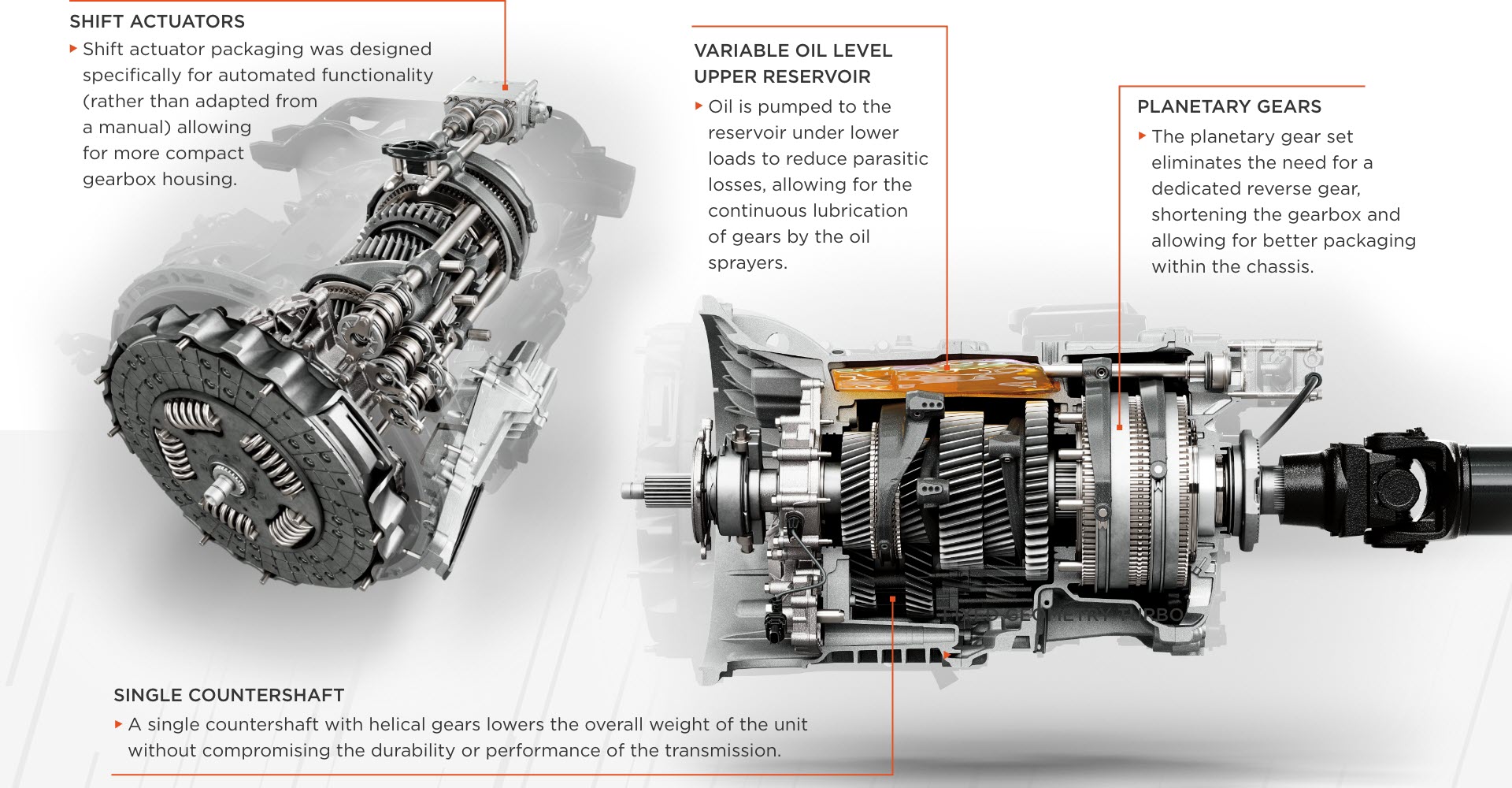

MAKING THE SHIFT

The all-new, fully automated T14 manual transmission was designed in-house from the ground up. It’s a 14-speed overdrive transmission that is optimized to deliver peak fuel economy performance in direct drive (13th gear) during typical load. The transmission has an electronically controlled clutch actuator that works in sync with the engine to deliver faster, smoother shift performance. Since it does not consume air during complicated maneuvers – like when you’re backing a trailer into a tight loading dock – the driver never needs to stop and let the air recharge. The T14 also uses an integrated oil to water coolant system to optimize temperature regulation in both hot and cold environments. This advanced feature is one reason why the T14 is able to achieve an unlimited Gross Combination Weight Rating (GCWR)